IUPAC Name

Tapioca Starch

Cas Number

9057-07-2

HS Code

1108.14.00

Formula

C27H48O20

Industry

Food Ingredients

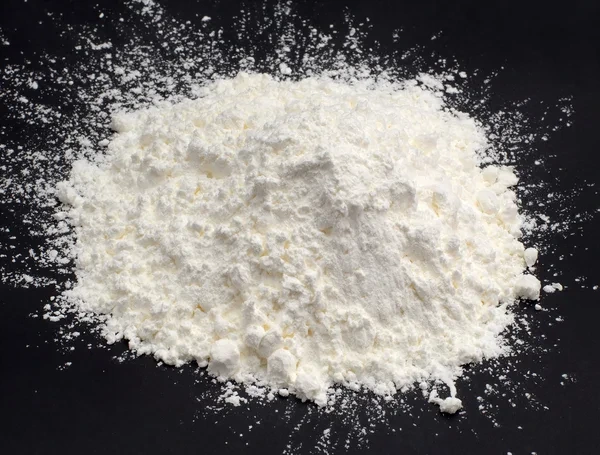

Appearance

White Powder

Common Names

Cassava Starch, Starch, Tapioca Starch

Packaging

25 Kg PP/PE Bags

Brief Overview

Starch is obtained naturally by extracting it from the grain or root of cassava, a type of root vegetable. It is readily accessible in the commercial market in the form of a dry powder, with its characteristics customized to meet particular needs. Its primary utilization is in the food industry, chosen for its suitability due to the absence of certain properties necessary in other industries.

Manufacturing Process

The production process of tapioca starch involves three key stages: preparation and extraction, purification, and water removal. Initially, cassava roots are washed and peeled, and the resulting pulp is strained with water. The next step focuses on purifying the extracted starch through sedimentation and centrifugation processes. The last stage involves eliminating water, accomplished through the drying process.

Food Industry

Different types of modified starch are utilized in the confectionery sector for a variety of functions, such as creating gels, thickening, stabilizing texture, improving foam, controlling crystal growth, promoting adhesion, facilitating film formation, and offering a glaze. In particular, modified tapioca starch plays a role as a colloid stabilizer in beverages that include solid components.

Adhesive and Glue Industry

Starch demonstrates its effectiveness as a natural adhesive, leading to the development of two types of adhesives: modified starches and dextrins. These find application in the creation of both roll-dried and liquid adhesives. Tapioca Starch, in particular, is highly regarded in the adhesive sector due to its impressive binding capacity and the substantial viscosity it attains when mixed with water or specific chemicals.

Textile Industry

In printing, modified starch is commonly utilized to achieve a more consistent print and to prevent contamination throughout the printing procedure. Usually, a preferred option for this purpose is a pregelatinized modified starch.

Other Applications

During the third stage of paper production, a specialized condensed paper is formulated specifically for applications such as book covers, calendar paper, and boxes. This process incorporates the utilization of thin boiling starches, more sophisticated modified starches, or the jet-cooking of native starch with enzymes.